- Supply Chain Strategy

- Supply Chain Network Design

- Inventory Management & EOQ

- Route Optimisation

- Distribution Logistics Tendering

- Fulfillment & Warehouse Logistics

- Last Mile Transport Tender

- eSCM & Supply Chain Analytics

Route optimisation - Reduce costs & increase productivity on the last mile

The last mile is considered the most cost-intensive part of most supply chains. Logistics on the last mile is highly individual and on a very small-scale, difficult to fully comprehend, and often not easy to standardise. At the endpoint of the supply chain you naturally meet the customer, who usually has no standardised requirements and is not always available to receive the goods. In today's customer centric world, it is typical to align oneself with the customer, which is why on the one hand processes are becoming more inefficient and on the other hand flexibility is required. Goods movements towards the end of the supply chain are mostly small and can only be enacted through relatively high expenditure on personnel.

In their efforts to use personnel and fleet resources efficiently in the last mile, many companies fail to meet the logistical challenge of optimal routes.

The opportunities available through route optimisation, which lie especially in the last mile, are often enormous. If the company’s own and external resources can be better utilised, productivity and the distance travelled can be increased, and in some cases trips with a negative contribution margin can be cancelled or rescheduled, savings of between 20% and 35% can be enabled.

Professional route optimisation on the last mile demands everything from logistics experts to realise the high potentials - the selection of the right software, the design of the right processes, and a practical approach to implementation.

In the following, we consider questions that are generally valid for the various forms and purposes of route optimisation and provide suggestions on what to look out for:

- What should be considered in the design and implementation of route optimisation and in the selection of software?

- Why route optimisation can never reach its full potential without sufficient integration.

- How can route optimisation, especially on the last mile, achieve the best results?

- 2 common, practical pitfalls within route optimisation.

What to consider in the design and implementation of route optimisation and in the selection of software?

If you don't yet have effective tour planning in your company or you are still at the beginning of your route optimisation initiative for the last mile, then here are some things to look out for.

Route optimisation is based on 3 cornerstones: data; personnel & methodology; and software. Shortcomings in any of these 3 aspects can have a huge impact on the results of the optimisation and the success of the project.

Data

You get out what you put in: The results and their usability can only be as good as the data on which they are based. It is therefore important to take into consideration the quality and reliability of the data, and how up to date it is, already during the setup of a route optimisation initiative. In general, optimisation should only be carried out with correct data – it is therefore often more advisable to start with annual strategic route optimisation and then move on to more regular or even daily route optimisation when data availability improves.

To maintain a good database, processes for regular data review and data organisation are useful. Databases to consider include:

- Customer master data (customer numbers, link to billing, orders, etc.)

- Location and depot data (opening hours, loading and unloading times, item availability, etc.)

- Address data (address data and, if applicable, geo-coordinates for delivery)

- Order data (order quantities, time windows)

- Fleet data (vehicles, availabilities, speed profiles)

- Driver data (working and driving times, quality logbook, driver's license registration & training status, etc.)

- Company data (prices, pricing models, conditions, etc.)

- Trip data (GPS information and times, etc.)

For some data sources, it is possible to regularly transfer up-to-date information via interfaces to a maintained primary database. In order to ensure track & trace for delivery or to use current trip data in billing and scheduling, also continuously updated data from the ordering and GPS systems is required.

The technical possibilities offered by modern software are advanced, but require excellent and regularly updated data. The selection of an appropriate optimisation approach with feasible data quality requires experience, knowledge of the available solutions, and precise analysis to determine the data level and quality that is realistic and affordable for the company.

Personnel and processes for route optimisation

Traditionally, many companies have entrusted on-site logistics specialists with route optimisation for their last mile operations. Such specialists are characterised by having excellent local knowledge, good logistics experience, and a good relationship with those working at an operational level in the company.

Contemporary, professional route optimisation places new demands on the role. Analytical skills and affinity with and understanding of optimisation methods, data, and technology, combined with the local knowledge and relationships with the operational departments, are required to optimise transport logistics routes as a whole. Local knowledge and local involvement will continue to be important, but the trend is moving toward a complementary, higher-level, centralised, data-based role.

Route optimisation software

As different as the use cases are, as diverse is the range of software available for route optimisation on the last mile. In order to select suitable software for a specific use case and strategic orientation, 3 things are particularly important:

- The strategic target system to be achieved through route optimisation

- Understanding of the current state of the data as well as the logistical processes and procedures on site, both in the dispatch department and at the customer's premises

- Knowledge of providers, mapping materials, optimisation heuristics, and software suitability of the various solutions for the individual use case.

Selecting suitable software requires not only knowledge of the supplier market, but also an understanding of the situation on site. Since, in addition to the selection and implementation of the software, the training of the employees and coordination of the processes is particularly time-consuming, the decision should be well-founded, the software and data should be suitable, and the processes should function properly.

Why route optimisation can never reach its full potential without sufficient integration

Every logistics specialist knows that logistics is not a self-contained system, but creates value by moving goods and commodities along the entire supply chain. High quality logistics means collaboration and integration - this is equally true for route optimisation software.

When you look at the challenges of logistics without reviewing the area it interacts with, you often find yourself in a maze of requirements and restrictions. One of the most severe restrictions are the requisite delivery time windows. If these are mandatory, optimisation can only be implemented for the downstream operation. If the time windows are too narrow to reach customers in the same region in one journey, an extra vehicle may have to be used, a logistics solution only that in practice can be found time and again.

In many cases, logistics is optimised within set restrictions that could have been changed. Often the reason is that it hadn´t been discussed or that the decision wasn´t made in a holistic manner. The illustration shows a client example, whereby with the cooperation of logistics, sales, and branch management, the trips that were not strictly required by the customer could be identified and the number of daily trips could be reduced. In addition, an extension of the delivery windows was allowed through an ABCD customer logic review. The scenarios developed show savings of 10 to 46% compared to the original route mapping and also examine the customer impact in each example, which was discussed with the sales department and the customer before implementation.

These examples illustrate that logistics – especially when it comes to route optimisation – must do more than optimisation within faits accomplis. Transport logistics, especially the last mile, is one of the most cost-intensive areas in many companies. Therefore, route optimisation must involve the integration of transport procurement, sales, shipping, and other adjacent departments, in order to jointly agree processes and restrictions in such a way that the overall value to the company is improved. Industries with a strong sales orientation, such as wholesale, are particularly susceptible to unilateral logistics decisions.

Pricing models, external carriers, delivery windows, vehicle requirements, and others are examples of parameters that should be included in such initiatives in order to achieve the best possible results through route optimisation.

How do you achieve the best results through route optimisation?

In order to achieve the best results in route optimisation, in addition to good data and suitable software, one thing is needed above all - logistical degrees of freedom and the right methodology.

When we talk about degrees of freedom, we are referring to the design freedom for repositioning an approach compared to the reference route. If, for example, the time frame between earliest departure and latest arrival is increased, there are more options for scheduling a stop in a cost-optimal way.

Depending on the logistics system, restrictions more or less prevent the mathematically most cost-effective route from being determined – therefore, one of the biggest levers in route optimisation is to scrutinise these restrictions from a holistic perspective. In addition to customer time windows, among the most decisive restrictions are: vehicle capacities, driver and vehicle availabilities, and order and departure times and locations. If an analysis of the restrictions reveals that the cost savings from relaxing the restriction are greater than the added value from keeping it in place, then action should be taken in a holistic manner. To have this conversation, the task of a route optimisation initiative is to simulate the effects of these restriction relaxations and to demonstrate the added value.

In addition to the degrees of freedom, the right methodology is hugely important. Many delivery networks have – especially in the last mile – different transshipment, transfer, or departure points. With such multi-level networks, contemporary route optimisation software reaches its limits. In order not to forego the advantages of multi-level systems, multi-level optimisation can be carried out heuristically with a suitable approach – this requires above all analytical and logistical competence in order to find permissible solutions in the specific case.

Another lever that can often be used is found in networks operated with external transport forwarders. If the utilisation of drivers and transporters is taken into account in the route optimisation, considerable savings can often be achieved in the price conditions because the logistics provider achieves better resource utilisation.

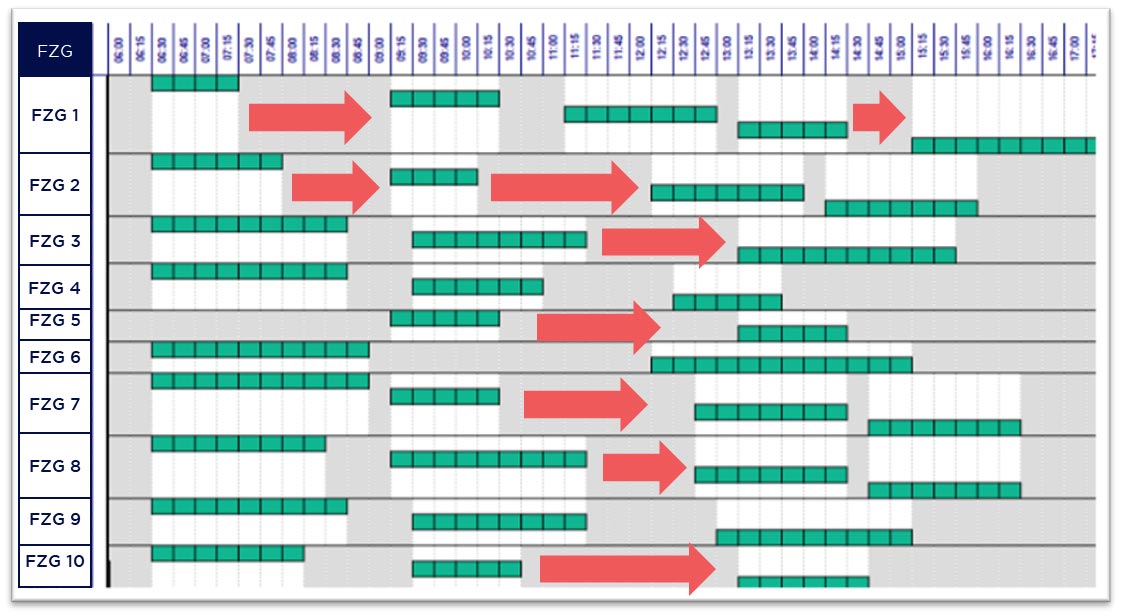

The following example shows the vehicle allocation and duration of individual wholesale milk run tours (green) spread over the day. Tours going to the same region were assigned to a vehicle and driver based on driver location knowledge. The breakdown shows significant idle times (red arrows) between tours as a result. Even with pricing models that price individual tours or mileage, the transport operator will not be able to avoid factoring-in the costs incurred by idle time. With the help of route optimisation, the routes and assignments could be changed in such a way that idle times were reduced as far as possible.

2 common practical pitfalls in route optimisation

In the following section, we describe two common pitfalls that we have observed in practice. In one case, the new route plan could not be rolled out; in the other, the results of optimisation were far from optimum.

A common and fatal mistake is to implement route optimisation based on inaccurate data and incorrectly set vehicle profiles.

In order to properly follow newly mapped routes without serious delays or overlong journeys, the vehicle profiles in the software should be matched with as many actual trip profiles as possible. For individual routes on different roads and at different traffic times, the speed profiles should be adjusted in the software so that the replication in the software matches the real values. Separate profiles for rush hour are recommended as well as adjustments of the most used roads in the map profiles. A sufficient number of GPS observations are particularly suitable for making adjustments.

After a certain amount of change, before newly created tours are implemented, it is advisable to test the new tours for their driveability through completing empty runs.

The holistic optimisation of a network can lead to complexity and challenge in terms of computing power. Also, it is often the case that, methodologically, companies do not consider multi-stage optimisation. As a result, many companies optimise only small sub-areas or even only a daily selection of a sub-area of a network.

While this approach increases handling and speed on the last mile, it can neglect significant potential for optimisation because the individual order points have not been taken into account. We recommend optimising area- and time-based constraints of a network individually only if the set of stop points and degrees of freedom is sufficient to form efficient tours.

Another often-observed error is optimising according to an incorrect parameter. The parameter ‘capacity’ can be restrictive when there are no time constraints and the volume-based utilisation of a vehicle determines the end of a tour, but it can be the wrong optimisation parameter in a scenario where the time windows are narrow. A network might be time-unconstrained at night and time-urgent during the day due to opening hours and ordering and pickup times. In this example, optimisation according to volume-based capacity is certainly not a bad criterion at night, but during the day the time requisites are much more important and should be weighted higher. In general, if you want to optimise costs, your software should also perform optimisation according to cost. In the best-case scenario, all cost factors can be included in the total cost equation for optimisation, and therefore be fully considered.

Conclusion on route optimisation

With the wide range of available options and the inevitable flurry of marketing from service providers, key success factors for route optimisation are often lost:

- Clean data and processes

- Suitable software and trained employees

- Value-add methodology and the integration of adjacent business units

Even today, the field of route optimisation - particularly on the last mile - is often underestimated in terms of its complexity and its potential value contribution.

OCM offers comprehensive support in route optimisation and can advise you on how to optimise your logistics sustainably through effective route optimisation. In addition to supporting you in the development of internal know-how, we are also happy to help you devise and implement your new strategic route network.

We would be happy to present our approach and project modules in this regard, or to discuss solutions based on your challenges.

Our project modules at a glance:

Logistics optimisation & Supply Chain Consulting modules

Logistics & SCM Opportunity Assessment

- Benchmarking & maturity testing

- Identification of opportunities & action plan

Transport Partner Management

- Transport partner strategy & professionalisation

- Securing resources and resource training design

Transport Tender

- Competition, effective transport tendering, fact-based negotiation

- Transport cost reduction

Freight & Logistics Tender

- Competitive pricing, quality, and performance assurance

- Individual weight-distance matrix

Warehouse Optimisation

- Efficient warehouse logistics & layout

- Optimised processes & working capital

Logistics Cooperation

- Optimising logistics through synergies

- Finding a fair and stable collaboration model

Route Optimisation

- Distance and route reduction

- Reduce resource & logistics costs

Supply Chain Network Optimisation

- Optimise delivery times, service levels, & processes

- Reduce working capital

Inventory & Order Management

- Optimal order quantity & stock on hand

- Optimise working capital

Fleet Optimisation

- Fleet concept tailored to requirements

- Cost optimisation

Supply Chain & Logistics Strategy

- Sustainable maximum value contribution of the supply chain

- Clear objectives, concrete measures

Digital Logistics Management & Reporting

- Information advantages in speed, scope, & significance

- Efficiency through automation, data integration & process simplification

Interim Supply Chain & Logistics Manager

- Rapid response: candidates within 48h

- Matching of requirements and assessment of suitability using logistics experts

- From dispatcher to logistics manager

Short-term staff shortage? Unexpected need for action?

Learn more