The S&OP Process: A Fundamental Driver of Cross-Departmental Collaboration

An excellent quarterly sales performance couldn’t be realised because the extra stock has not been ordered in time. A dip in customer demand has lead to a swollen inventory and a crowded warehouse. A global supply shortage hasn’t been communicated to the sales team, causing cancelled orders and unhappy customers. And all of this felt distinctly avoidable.

Sound familiar?

Such undesirable scenarios, and a whole host more, could be prevented through effective Sales & Operations Planning (S&OP). In this article, we examine the purpose and benefits of Sales & Operations Planning, delve into the process itself, and give advice on how to implement S&OP in your company.

What is S&OP?

Simply put, S&OP is an organisational process that improves transparency, communication, and decision-making across all the departments involved in ordering, manufacturing, and delivering the product to a customer.

In essence, it is a cross-functional process that brings together a number of disparate teams in order to find a compromise that works best for the company. Sales & Marketing, Demand Planners, Supply Chain, and Finance share plans and forecasts, and convene in regular meetings to align objectives and collaborate on pressing issues, all under the steer of an Executive.

An effective S&OP process is founded on good data, accurate forecasts, timely planning, structured communication, and effective escalation. Ultimately, its purpose is to ensure the customers’ needs are fulfilled while avoiding waste.

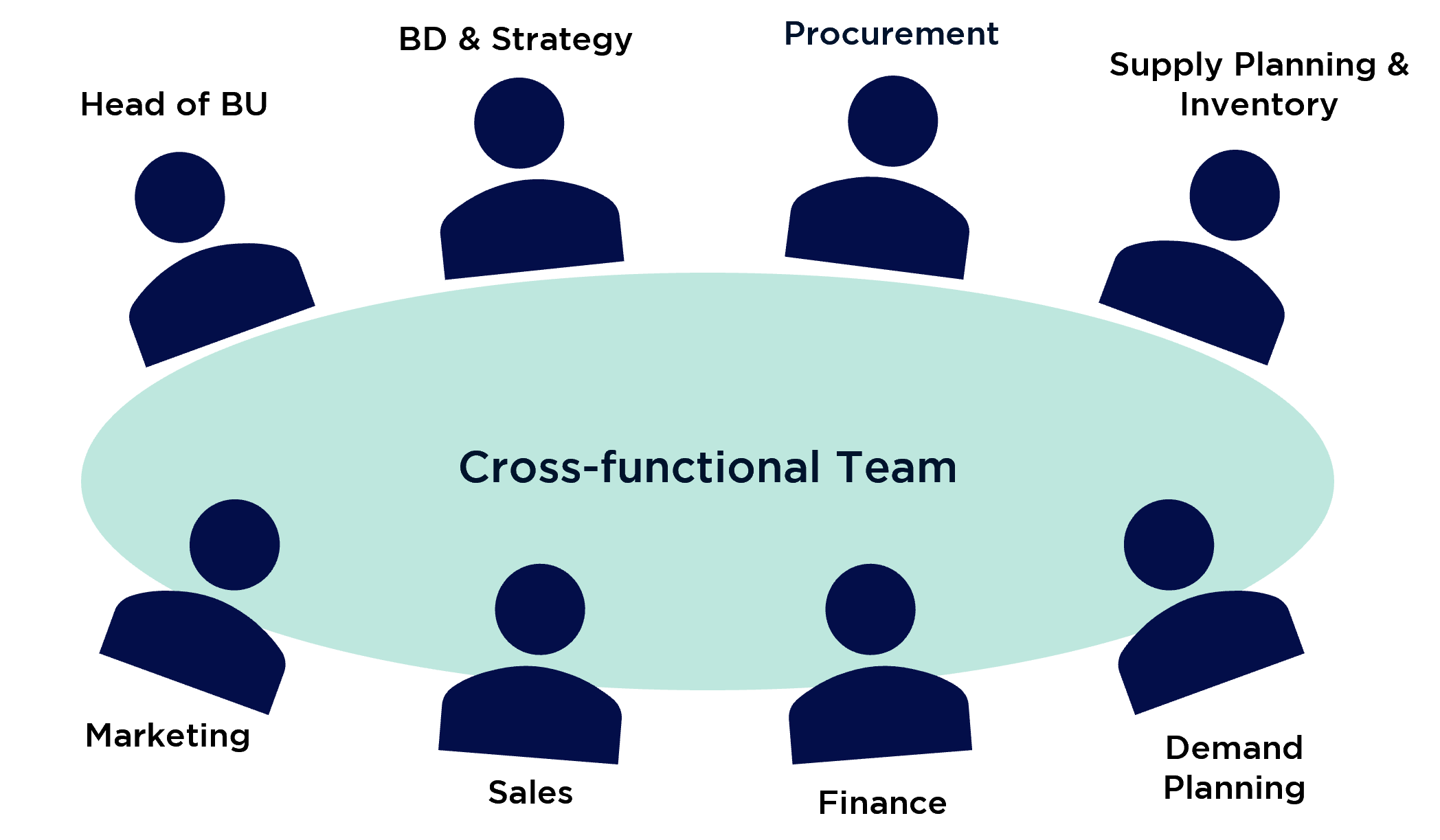

Who is involved in the S&OP process?

Purchasing has calculated with the next best price level at the supplier and orders a certain outstanding quantity to reach it. Inventory management, however, is trying to clear long overdue slow-moving items and reduce inventory. Yet, production planning is currently unable to release free capacity because demand planning forecasts other products and these must be given priority. Sales is trying to bring back a leaving customer with quantity promises for another product, without taking into account the current supply bottleneck for certain components.... One could continue the list like this. In short, each department has different goals and often these are in conflict with each other. Since ultimately all decisions should be made in the best overall interest of the company, a joint dialog and holistic consideration of the respective departmental goals is necessary.

To that end, S&OP isn’t the work of a single, all-knowing, all-powerful stakeholder; it's a collective effort between several inter-dependent departments, all with equal importance.

An effective Sales & Operations Planning Process involves the following departments and stakeholders:

- Sales, Business Development & Marketing: In the S&OP process, the Sales and Marketing teams are responsible for conveying the sales strategy for the coming period. This includes promotions, product launches, product alterations, and product sunsetting. They also provide analyses on how their strategy will affect the sales volumes by, for instance, taking into account volume uplifts due to discounts and sales cannibalisation. In instances where the product itself changes regularly (e.g. complex technology rather than steel rivets), the Sales team may seek additional input from the Product Team, who can provide more in-depth information and rationale behind the product strategy.

- Demand Planning: In conjunction with the information provided by the Sales Team, the Demand Planner uses past sales data and product forecasts to create an accurate demand profile for the coming period. This takes into account a number of factors, including seasonal variation, economic conditions, market conditions, competition, and more.

- Production planning:Production planning attempts to translate the existing demand planning to the production requirements. The tasks include lot-size planning, scheduling, capacity planning and sequence planning. In other words, it must be planned when which quantities are to be produced, how and by whom/which machine. Among other things, machine and personnel resources, material availability and sales deadlines must be taken into account.

- Supply Planning: The Supply Planner is responsible for reviewing the status of the supply chain. This means providing an understanding of the current stock conditions while also reviewing the external supply risks, for example, product shortages or logistics issues. The Supply Planner then develops an accurate picture of the supply capacity for the upcoming window.

- Procurement: Similar to the Supply Planner, Procurement is responsible for reviewing the company’s procurement position and risks. This includes factors such as price fluctuations and supplier issues. The amount of input required from Procurement is dependent on the business model. For instance, pass-through vendors will require a large input from Procurement, whereas OEMs may combine Procurement’s input with the Supply Planner.

- Finance: Finance is an extremely important stakeholder in the S&OP process. They are ultimately responsible for the budget, which becomes an enabler or limiting factor for all of the above. They review the last period’s performance and use it to create baselines and adjustments that the S&OP team must adhere to.

- Executive: In an effective S&OP process, the executive should be C-suite or even CEO. The executive chairs the meeting, not only to provide the process with gravitas but also to resolve conflicts and issues as the highest point of escalation.

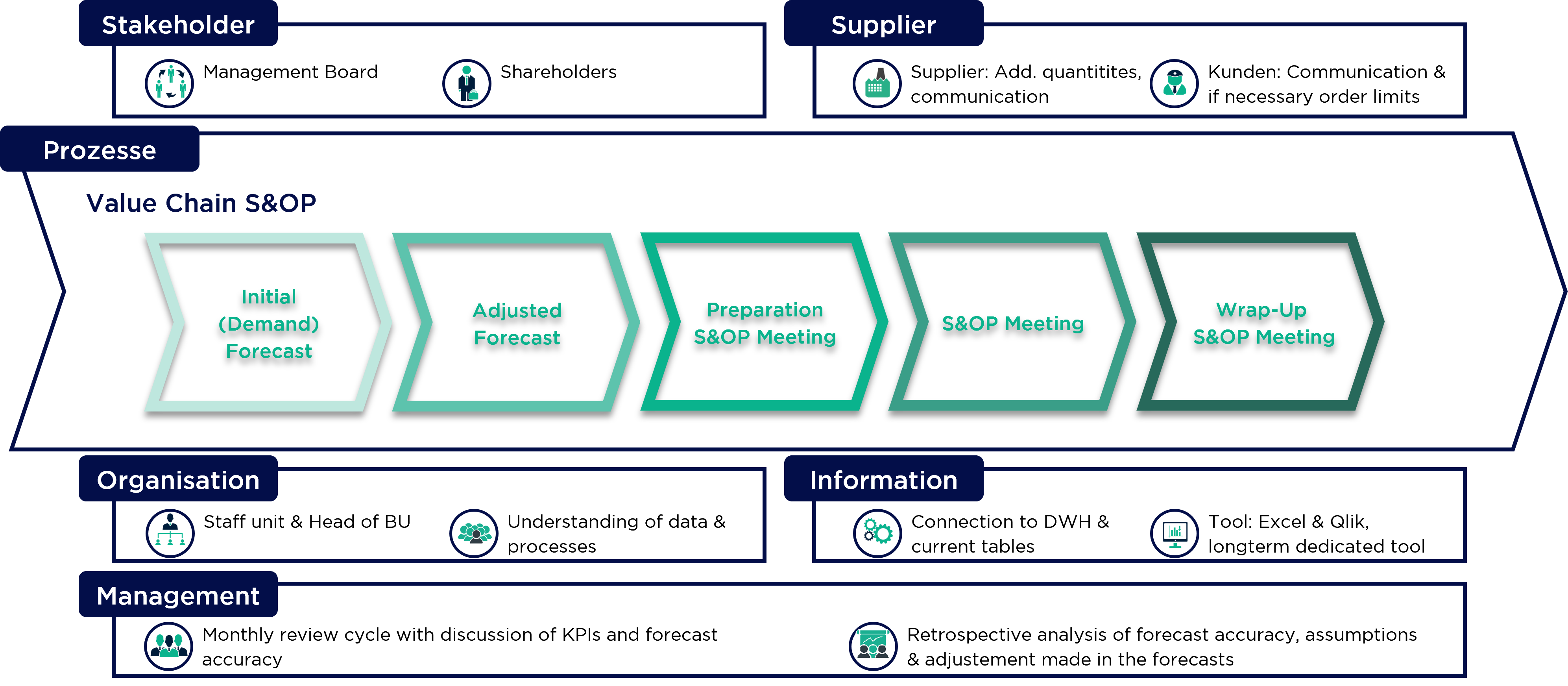

What does the S&OP process entail?

There are three key stages to the S&OP process, which take place at a regularity that suits the organisation and the product. Typically, they are monthly or quarterly.

1. Prior to the S&OP Meeting

The various functions involved in the S&OP process perform their duties before the S&OP meeting itself. These include:

- Sales, BD & Marketing provide an overview of the strategy for the upcoming period, including promotions and launches. Provide this information to Demand Planning.

- Demand Planning use the information from the Sales, BD & Marketing teams to turn an Initial Demand Forecast into an Adjusted Demand Forecast, which can then be used by the other departments.

- Production planning: Creates a Production Plan based on the Adjusted Demand Forecast, which ultimately must also be reconciled to the capacities of the Procurement Plan and must be compatible with the Supply Plan.

- Supply Planning, in collaboration with Demand Planning, reviews the current status of the supply chain, including both internal and external supply risks. Produce an overview of stock levels, inventory targets, safety stock, and scheduling and work this into a ‘Supply Plan’ depending on the Production Plan.

- Procurement taking into account supply contracts, pricing, and supplier status, determines the minimum and maximum procurement quantities and work this into a ‘Procurement Plan’.

- Finance reviews the previous period’s performance and the next period’s financial forecasts to produce the budgetary constraints.

Given the level of interaction required between the functions, it can be useful to hold a ‘Pre S&OP Meeting’ or bilateral coordination meetings. This meeting typically takes place without the executive and is used to reconcile plans ahead of the S&OP Meeting proper. This is particularly important when information is flowing in a circular fashion. For example, in a situation where the Supply Planner needs to offload some stock due to an approaching expiration date, and so the sales team works up a new promotion, in the process altering the demand profile; in this case, the sales, demand, and supply plans all need to be adjusted based on the communications between the teams. Finance must be involved at this stage to ensure that any reconciled, consolidated plan is within budget.

The goal of this phase is to create a preliminary consolidated S&OP plan. In preparation for the S&OP meeting, each department should analyze this plan in terms of departmental requirements, identify risks & derive necessary measures. This way, these can be presented in the S&OP meeting and decisions can be made efficiently.

2. The S&OP Meeting

The S&OP meeting is attended by all the key stakeholders, including the executive, who typically chairs the meeting. The objective of the meeting is to sign off the consolidated Sales and Operation Plan, which will then inform activities for the next period. The meeting is also a forum in which to address any conflicts and resolve issues.

The meeting typically includes the following agenda points:

- Performance review for the last period against agreed KPIs

- Presentation of the Sales, Demand, Supply, and Procurement Plans to the executive, including identified risks & necessary measures

- Review of new and carried-over risks

- Consensus building on a consolidated plan for the next period

- Sign-off

An effective S&OP meeting involves collaboration and compromise between the departments; in essence, it is a consensus-building exercise.

3. After the S&OP Meeting

Following the S&OP meeting, the plans are adjusted as agreed and the information disseminated to the relevant teams. These activities tend to occur within the departments, though it is often useful to share the final plans among departments to ensure there are no misunderstandings. Any risks or obstructions that become apparent at this stage should also be shared; however, if the process is working properly such occurrences should be infrequent.

If, for whatever reason, unresolved issues remain after the S&OP meeting – i.e. issues that could not be resolved by the attending executive – they should be escalated to the board or equivalent authority. Any subsequent decisions made by the board will have to be incorporated into the agreed plan.

Once the plan has been implemented, it's probably time for the next S&OP cycle to begin.

The Benefits of S&OP

An effective S&OP process can transform the effectiveness of an organisation. The key quantifiable benefits are as follows:

- Sales growth through increased reaction speed, better delivery capabilities, reduced out-of-stock, and optimum launch conditions for new products

- Cost reduction through reduction of freight costs due to forward planning, improved order times and quantities, and a reduced need for costly, emergency interventions

- Working capital optimisation through planning accuracy and optimised inventory levels

The benefits of an S&OP process are not only limited to those that impact the balance sheet. The process can be seen as a broader initiative to enhance collaboration between departments, breaking down the siloes that often exist within organisations. To that end, the benefits of the S&OP process reach beyond the process itself by fostering better relationships between stakeholders.

S&OP Best Practices: 8 ways to ensure your S&OP process runs smoothly

Perhaps your organisation doesn’t have an S&OP process, or it does but it doesn’t work. Whether you’re looking to implement or transform an S&OP process, here are 8 ways to ensure your S&OP process is effective.

All new processes need buy-in from the right stakeholders, and S&OP is no different. In fact, given it is cross-departmental – and not to mention time-consuming – S&OP needs buy-in more than other processes might. An effective way to gain buy-in is to nominate an S&OP champion who "markets" the process and increases acceptance in the relevant departments. This is preferably the same executive who chairs the meetings.

Training is important for those directly involved in the S&OP process as well as those outside of it. Operatives in each department need to understand how their actions affect the operations of other departments; for example how new delivery lead times agreed by a salesperson affect the deal recently struck by a procurement colleague. That’s not to say that every operative needs omniscient knowledge of every process in the company, but that a broader understanding will help them make decisions for the greater good while accepting the rationale of those decisions made in the S&OP meeting.

The output of an S&OP process is only as good as its input, and that’s especially true for the data. Before proceeding with a fully-fledged process, ensure the data is in good order by auditing each department’s data. If there’s an opportunity to integrate and consolidate data sources, then, depending on cost, it may be a change worth pursuing.

In addition, good data should always come in aggregable & disaggregable data structures. This has various reasons:

- Each department has different perspectives & requirements for data work. Thus, the same base data can be prepared for the corresponding department depending on the aggregation level.

- High-level considerations enable fundamental analyses and generally valid adjustments.

- Nevertheless, the detailed level is also necessary for some observations, especially in order to derive department-specific measures.

On the one hand, it is very difficult to create a reliable forecast with pinpoint accuracy, and on the other hand, the informative value decreases. If you give only one forecast value per month, this is probably the expected average value. However, the expected fluctuation around this mean value is missing. Since this provides very valuable information, it is always advisable to use forecast corridors. These can be, for example, statistical confidence intervals, manually determined minimum and maximum values, conservative and optimistic forecast values or similar. The given corridors convey the range between expected good development and expected worse development in order to better assess any risks and derive appropriate measures.

As with any other process, effort and benefit must also be in the right proportion in S&OP. The 80/20 principle is often helpful here. 80% of the impact can be covered with 20% of the effort. The remaining 20% of the impact corresponds to 80% of the effort, which in most cases cannot be justified in terms of resource efficiency. Therefore, a detailed analysis is required as to how processes can be optimized, which considerations create added value, which sub-steps can be neglected, etc.

Another aspect in the effort/benefit optimized process are technologies and the user experience: Excel spreadsheets and manually produced PowerPoint presentations slow the process down and lead to human error. A number of S&OP technology solutions exist, either as standalone packages or as bolt-ons to enterprise software. These can help you run ‘what if’ scenarios that show in real-time the impact of decisions. Using such tools can save time and trouble and make your S&OP process more effective.

Different business models, different industry or different products, different organizational structure, ... - what fits one company often does not meet the requirements of another. Processes, data structures and tools need to be customized to your company in order to make the S&OP process efficient and achieve the intended goals. Even though software providers often advertise it, in the rarest cases "standard solutions" work. Certain configurations & customizations are always necessary so that your company really profits from the implementation.

In this day and age, it’s easy to get bogged down in a sea of information. Selecting and agreeing on KPIs streamlines the decision-making process. It also provides measurable success factors with which to assess the performance of the S&OP team.

Often the aforementioned aspects are not easy to define and the following questions arise, for example: What are the most suitable process steps for your company? Which software best supports your requirements? Which data should be included, and to what level of detail? These questions can often only be answered by testing these aspects in the S&OP process itself. Therefore, we recommend to consider the joint definition of the aspects as a "Journey". This starts with a Minimum Viable Product ("MVP"), i.e. a product that meets the minimum requirements. Necessary adjustments can best be formulated in use so that the S&OP process can be expanded together step by step. This way, all process participants are involved in the development, the direct influence promotes acceptance and the S&OP structures can be individually adapted to your company.

Sales & Operations Planning: Final Thoughts

A functioning S&OP process is a very powerful tool that creates true competitive advantages, especially in volatile times (VUCA). However, the prerequisite for this is the tailoring to the individual company, the processes, data and resource skills as well as the joint development under strong ownership of top management.

The S&OP process brings together key stakeholders from different departments to determine a cohesive plan for the coming period. This is to ensure that decisions made at departmental level have a positive impact on the company as a whole, and that risks identified by one part of the company are known to the others and mitigated accordingly. It does this by inputting accurate data and forecasts into a rigorous decision-making process while enhancing inter-departmental collaboration through a regular meeting schedule, all overseen by an executive.

The key to ensuring an effective S&OP process is achieving buy-in from the start, customized, efficient processes, and optimized data structures.

Here at OCM Management Consultants, we have a wealth of experience in implementing and transforming S&OP processes. If you would like to know more or are interested in one of our consulting modules, then please don’t hesitate to get in touch.

Logistics optimisation & Supply Chain Consulting modules

Logistics & SCM Opportunity Assessment

- Benchmarking & maturity testing

- Identification of opportunities & action plan

Transport Partner Management

- Transport partner strategy & professionalisation

- Securing resources and resource training design

Transport Tender

- Competition, effective transport tendering, fact-based negotiation

- Transport cost reduction

Freight & Logistics Tender

- Competitive pricing, quality, and performance assurance

- Individual weight-distance matrix

Warehouse Optimisation

- Efficient warehouse logistics & layout

- Optimised processes & working capital

Logistics Cooperation

- Optimising logistics through synergies

- Finding a fair and stable collaboration model

Route Optimisation

- Distance and route reduction

- Reduce resource & logistics costs

Supply Chain Network Optimisation

- Optimise delivery times, service levels, & processes

- Reduce working capital

Inventory & Order Management

- Optimal order quantity & stock on hand

- Optimise working capital

Fleet Optimisation

- Fleet concept tailored to requirements

- Cost optimisation

Supply Chain & Logistics Strategy

- Sustainable maximum value contribution of the supply chain

- Clear objectives, concrete measures

Digital Logistics Management & Reporting

- Information advantages in speed, scope, & significance

- Efficiency through automation, data integration & process simplification

Interim Supply Chain & Logistics Manager

- Rapid response: candidates within 48h

- Matching of requirements and assessment of suitability using logistics experts

- From dispatcher to logistics manager

Short-term staff shortage? Unexpected need for action?

Learn more