- Procurement Strategy

- Procurement Management

- Procurement Transformation

- Strategic Procurement & Category Management

- Operational Procurement

- E-Procurement

The procurement strategy – strategic sourcing

When asked, 8 out of 10 CPOs/procurement managers claim that there is a procurement strategy in place. If the same question is asked to budget-responsible colleagues and buyers, then this number decreases to 2 out of 10. It is clear what this means for the sourcing strategy in terms of orienting procurement for the coming year: a strategy which does not arrive at the operational level with well-defined objectives and tangible goals cannot be properly effective.

In this context, questions arise, such as:

- Why is a procurement strategy important?

- What are the tasks of the procurement strategy?

- Is an overarching category strategy missing?

- Is strategic sourcing sufficiently integrated in the company?

- Does the procurement strategy lack innovation and is it not forward-looking?

- Does your procurement strategy ensure the appropriate governance, cost, and performance measurements?

Why is a procurement strategy important?

Depending on the company, external expenditure usually ranges between 40% and 80% of a company´s total expenditure. The procurement strategy is therefore critical to most company’s competitiveness. For this reason, it is important that the procurement department, especially strategic sourcing, contributes to the development of the corporate strategy. Furthermore, the procurement strategy serves as the overarching guide for the daily work of the procurement department. Last but not least, the strategy defines guidelines and tools with regard to external expenditure for the wider organisation, paving the way for efficient cost management.

The procurement strategy typically covers a planning period of 3 to 5 years. It is developed by procurement management and the strategic sourcing department in cooperation with the executive board in accordance with the organisation´s corporate objectives. The status and goals of the procurement strategy are compared with the objectives at regular intervals and adjusted where necessary.

Tasks of the procurement strategy

As procurement derives its goals from the organisation's corporate objectives, the procurement strategy specifies in more detail how these goals can be achieved in the medium and long term. One key element of the procurement strategy is to ensure that the organisation and its suppliers are measured and managed in accordance with its goals.

Another important task of the procurement strategy is to define measures to achieve goals within a comprehensive category strategy. This considers the internal and external circumstances of the categories as well as the availability and capabilities of procurement resources.

In the main, however, the sourcing strategy focuses on answering elementary procurement questions within a changing business environment. These include: make vs. buy; global sourcing; the implications and specification of a mixed supply base; risk management; coordination of both supply and demand within the supply chain; and the exploitation of technological innovations, for example digital procurement.

Is there evidence of a lack of procurement strategy?

The symptoms of a poorly formulated or implemented procurement strategy can be diverse, and in individual cases can have different consequences. Below, we discuss the typical challenges of strategic sourcing in its procurement strategy, and propopose the initial approach to reaching a solution.

Does your organisation have an annual plan that lists all strategic and tactical procurement initiatives and activities? Or are the category managers heavily occupied by project procurement issues and ad hoc inquiries from the organisation, leaving little time for rigorous tenders and other supplier activities? The various categories handled by procurement organisations often do not differ in terms of the effort involved, the skill and number of resources responsible, the depth of involvement of operational stakeholders, and the time invested in innovative procurement concepts. Against the background of limited resources and the varying impact of cost categories on the company’s overall cost, this leads to suboptimal procurement results. In addition to escalating external costs, there often follows a drop in quality, delivery bottlenecks, and demotivated category managers, since they are rarely able to complete all their allotted tasks in a satisfactory manner within the available time.

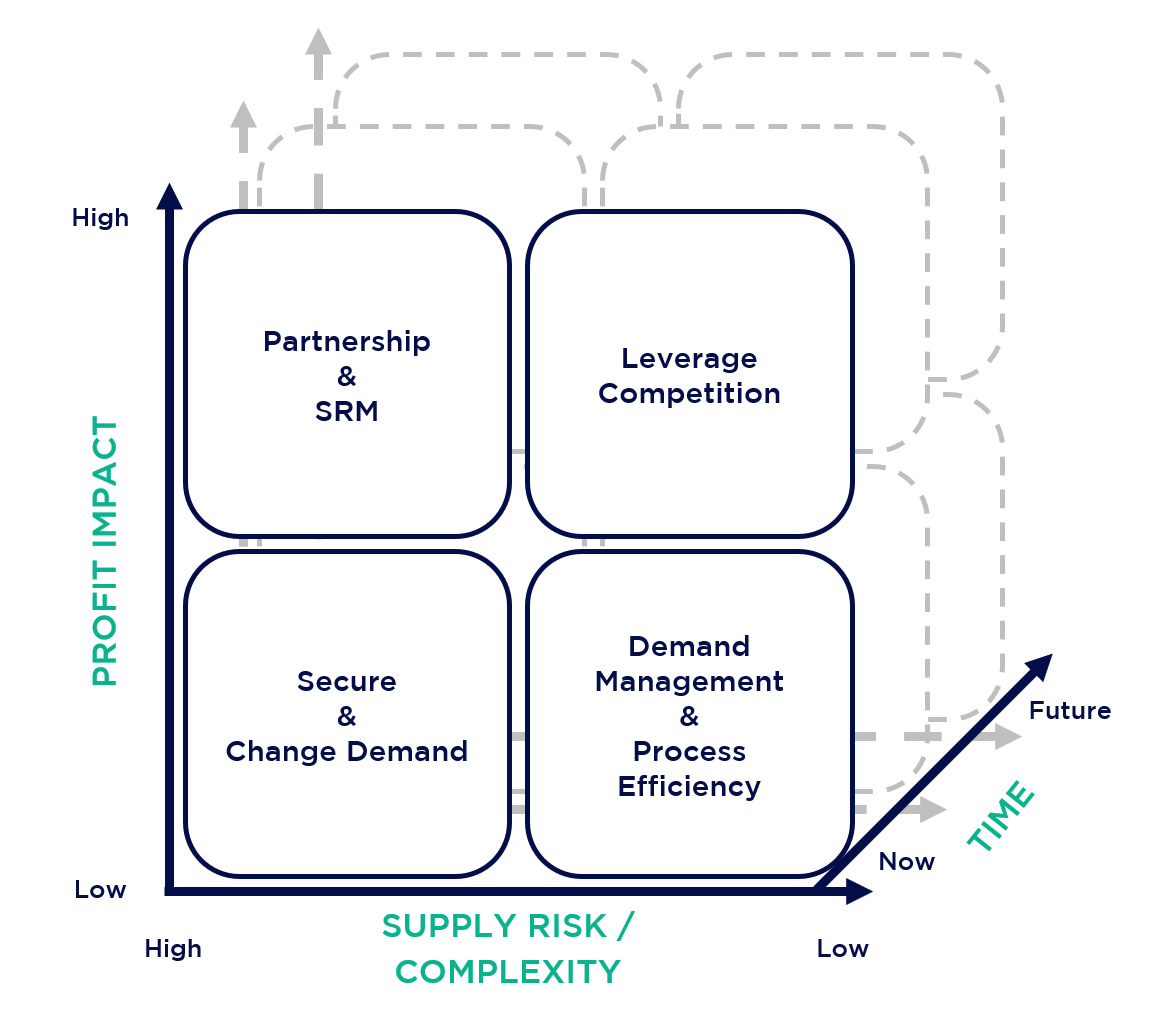

The fundamentals of a comprehensive category strategy are full cost transparency and a market-facing category classification. The savings potential and relative complexity of the categories are deduced from the existing price levels, historical procurement activities, and market benchmarks. Combined with the resource requirements, these two factors inform the high-level category strategy. The most important categories should be assigned the most capable resources and most effective measures. From all of these considerations the division of the resources and categories into strategic, tactical, and operational can be made, as well as an annual plan for procurement activities.

The causes of suboptimal procurement behaviour can lie both inside or outside the procurement department. One-dimensional “silo thinking” within the corporate functions, poor data transparency, or a lack of focus on the procurement strategy are all conditions under which procurement opportunities remain hidden and savings go unrealised.

Typical signs are:

- Reactive instead of proactive procurement behaviour

- Cost increases for materials or fluctuations in demand at the expense of the bottom-line

- The liability and costs incurred through defects in purchased materials remain within the company.

- Fixed agreements and conditions for the customer differ in duration and/or validity period to those of the relevant suppliers.

The optimal positioning and adjustment of procurement requires a multi-layered approach. OCM can help you make purchasing-affecting contexts visible and derive measures to minimise risks and to take into acccount costs relevant to purchasing within your organisation. The measures can be internal to procurement, internal to the company, or directed at the customer or supplier. In addition to content development, a change management programme actively supported by senior management is vitally important in embedding cross-departmental communication and process changes within the organisation.

An example of a process improvement initiative is the introduction of value engineering concepts, whereby strategic sourcing takes on a core function in the company. In value engineering projects, interdisciplinary teams pursue the goal of generating a cost-optimal product. The aim is the fulfilment of customer demands at the lowest possible external costs. For this purpose, Value-Orientated Design or Design-to-Cost concepts are applied. Focussing on the key characteristics and optimising the design is crucial in ensuring both cost minimisation and value maximisation. Value engineering offers an excellent opportunity to systematically solve complex issues, to leverage savings opportunities, and to maximise product yield. Successful value engineering therefore requires intensive cooperation between development, procurement, marketing, and production.

Digitalisation, outsourcing, global sourcing, near-shoring, design-to-value, e-procurement, crowdsourcing – these are the trend terms of recent years. The question is: are these just marketing measures and intriguing concepts that can't actually be implemented? It is noteworthy that almost all managers are familiar with the terms, but companies often have little or no access to them. In most companies, innovation in procurement is neglected for what are believed to be the more prestigious, less operational areas of the organisation. Despite their advantages and disadvantages, the trend terms refer to valuable concepts that, while not appropriate for every company, should at the very least be sufficiently examined and tested. Reasons for a lack of innovation are mostly the low prioritisation of strategic questions, insufficient resources, or a lack of experience in these concepts.

In line with your unique situation, we work with you to develop innovative sourcing strategies tailored to your needs and evaluate them according to the potential benefits and risks. We support the decision-making process and work with your organisation to develop the implementation plan to ensure a smooth rollout.

How has Procurement performed compared to last year? Have you lowered your costs and improved your quality and service level? What is your maverick buying quota? What did the procurement optimisation initiatives achieve, or why did they fail? Which are your best suppliers and how have they developed? Many procurement organisations are not yet ready to answer these questions. The most serious consequences are typically missed savings, mediocre to poor performance of your suppliers, or cooperation with the wrong suppliers. Misdirected or failed initiatives not only waste resources, they also frustrate the associated team.

When introducing a measurement and control system for your purchasing department, we help you to transform existing and future data into target-oriented, transparent, and comparable performance indicators. It is also important to bridge the gap between these performance indicators and company level reporting and, in particular, the total external costs in a period. The next step is the introduction of measurement and control processes and appropriate instrumentalisation, for example, through software support or the introduction of a corresponding function.

Results and added value through a good procurement strategy

When successfully implemented, a good procurement strategy can enhance competitiveness. It can be summarised in 3 main points:

- A strategic plan prescribing how procurement will meet the corporate objectives in the medium to long term, including: concrete measures; goals for the organisational structure; and the positioning of, and innovation within, the procurement department

- Resource-and-result-optimised category management, including: derivation of bespoke strategies; introduction of new and innovative procurement methods and tools; and the identification and definition of savings levers and targets.

- Measurement, control, and management, including: the introduction of targeted measurement and control instruments; and efficient processes for the clearance, management, and handling of all procurement activities.

OCM offers comprehensive support in designing your customised procurement strategy as well as its implementation with strategic sourcing via our comprehensive product offering: Procurement Consulting. Check out our OCM Strategic Impulse Series which presents selected insights that contextualise current geopolitical, technological, and economic developments with a specific focus on Procurement, Logistics, and Supply Chain Management.

We combine our proven approach for the development of a bespoke procurement strategy with the specifics of your procurement management, the resource requirements for its implementation, and a realistic future orientation in e-procurement.

We would be happy to present to you our approach and product modules, or discuss concrete solutions based on your challenges.

Our project modules at a glance:

Procurement Consulting Modules

Procurement Opportunity Assessment

- Benchmarking & Identification of Opportunities

- Tangible Action Plan for Implementation

External Cost Transformation

- Reduce costs & stop maverick buying

- Procurement Optimisation & Zero-Based Budgeting

Procurement Process Optimisation

- Procurement processes optimisation: fast, cost-efficient, digital

- Trained and invested employees

- Improving compliance

Strategic Sourcing

- Procurement Strategy & Cost Optimisation

- Increase quality & prevent maverick buying

Procurement Strategy Design

- Sustainable max. value contribution through optimal procurement strategy

- Reduce costs, optimise procurement processes

BI Cost Reporting

- Consolidated data sources

- Meaningful live analyses

- Fact-based decision making

Procurement Operating Model

- Maximising the value-add of the procurement organisation

- Optimise, measure, & control procurement processes

Training: Strategic Sourcing & Negotiation

- Buyers trained as specialists

- Putting theory into practice and implementing with support

Interim Procurement Manager

- Rapid response: candidates within 48h

- Matching of requirements and assessment of suitability using procurement experts

- From operational buyer to CPO

Should Cost Analysis

- Should Costing als Methode der Einkaufsoptimierung

- Der Weg zu Should Cost Analyse & Should Cost Modell

Digital Procurement

- Competitive advantages in speed, scope, & significance of information

- Efficiency through automation, data integration, & process simplification

Workforce Management

- Procure-to-pay cost reduction

- Fraud prevention

Supplier Management

- Efficient Cooperation

- Performance-based Supplier Management

Insurance Optimisation

- Cost Optimization

- Bespoke Optimal Insurance Cover